Polyurethane (PU) Products

Polyurethane Flooring comes in two kinds: Straight Polyurethane and PU Cement. The former is flexible at low temperatures and can bridge cracks. PU Cement, on the other hand, is the most popular type of flooring in the heavy-duty end of the market. It has the broadest range of chemical resistance and is very hard.

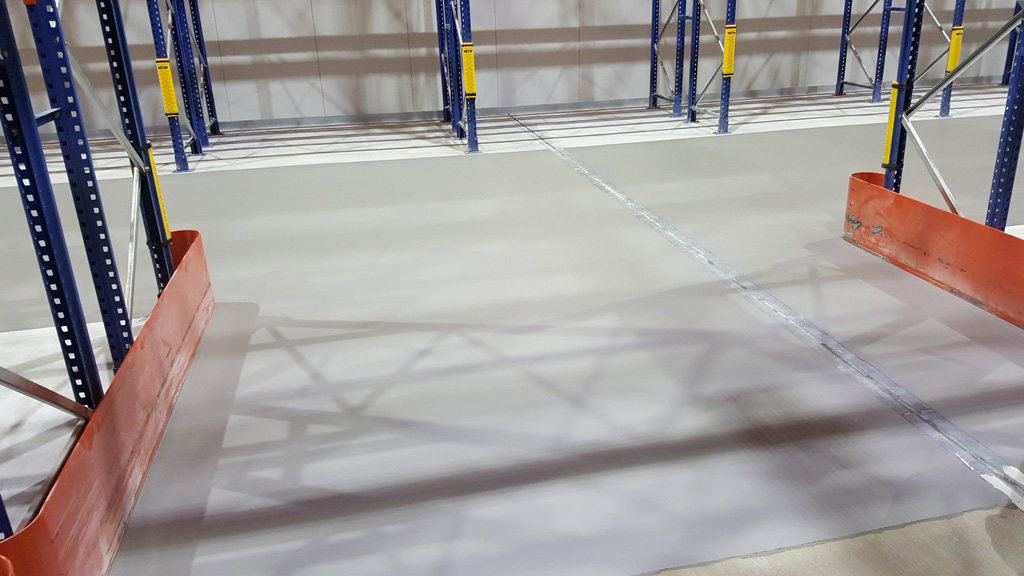

Polyurethane Cement sets fast and is useful for situations where we need to get in and lay a small floor in a very tight timeframe, or a large area in a new construction in just a couple of days.

Your account representative will be able to specify the best choice of PU Flooring for your particular application.

Every floor that we lay meets the Bethell Standard. It means that you get a floor that is the thickness you were quoted, with the slip resistance you need, made from the best quality products from a small group of the best product manufacturers around the world.